How is Welding Wire Used (Complete Guide With Pictures)

Over the years I’ve gone through a lot of welding wire. To think this simple wire is what bonds all of the welding jobs together that do for my customers. Without it, I wouldn’t even have a business. The question is how is welding wire used in the first place?

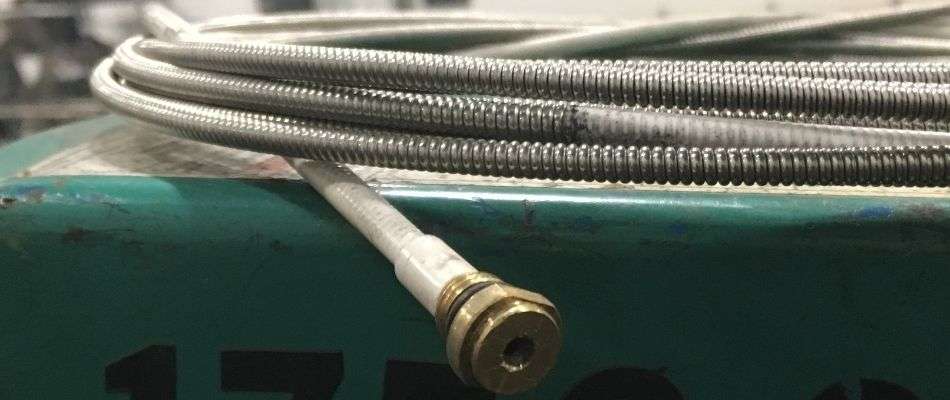

Welding wire comes in rolls that weigh between 10 to 60 pounds or more. The roll is placed on the feeder that pushes the wire through the liner up to the welding gun where it comes out of the tip. The wire then creates an arc when it hits the metal causing it to melt instantly creating a bead.

If you’re new to all of this and that sounds confusing then keep reading. In the rest of this article, I will show you exactly what welding wire looks like how it works with your MIG welder, and what it’s made of.

How is Welding Wire Used

If you’re new to welding and you’re trying to understand the basics of it then welding wire is just the start of it. In this section, I’m going to explain how it works.

1. Welding Wire Rolls

To start welding wire comes in rolls by the pound. You can typcially get them in as little as 10 pounders or 30 and 60 pound rolls depending on the type of machine you have.

If you have a small 110v or 220v unit then 10 pound rolls are common. If you high end 250 amp welders then you’ll likely use 30 or 60 pound rolls.

The wire is on the roll and tucked through a hole on the side of it to prevent it from unwinding itself off the roll.

The wire also comes in various sizes from .030, .035, .045, 1/16″, to 1/8″ wire. However I find .035 and .045 to be the most common sizes.

2. The Wire Holder

Next you have the wire holder. This is where you will put the wire so the machine can hold it and feed it through.

The wire holder has a one knob to hold the wire and a second knob that helps start and stop the roll from spinning.

Without the wire holder you would not be able to feed the wire through the machine.

3. The Feeder

Once the wire comes off the roller it is then feed through the feeder. The feeder is the part of the welder that pulls the wire off of the roll and pushes it through the lead.

The feeder puts pressure on the wire to push it through the lead. This is done using a set of rollers that are specificly sized to move it through the machine.

The feeder also has a spring tensioner that allows you to apply more pressure or less pressure on the wire depending on what is need to push the wire through the machine.

4. The Lead and the Liner

Once the wire passes through the wire feeder it then moves through the lead. The lead is the rubber outside that connects from the welder to the welding gun. The lead also pushes the welding gas through the gun as well

Related Article: To learn more about welding gas check out my beginners guide here.

Inside the leads is the liner. The liner is a replaceable consumable that holds the wire as it flows through the lead. A liner looks sort of like a steel cable but has a hole through it to move the wire so it doesn’t bend or break.

Finally, the lead can vary in length anywhere from 5 foot to 20 feet or more. In my shop I use 15 foot leads the most because they are still short but long enough to most project I weld.

5. The Welding Gun

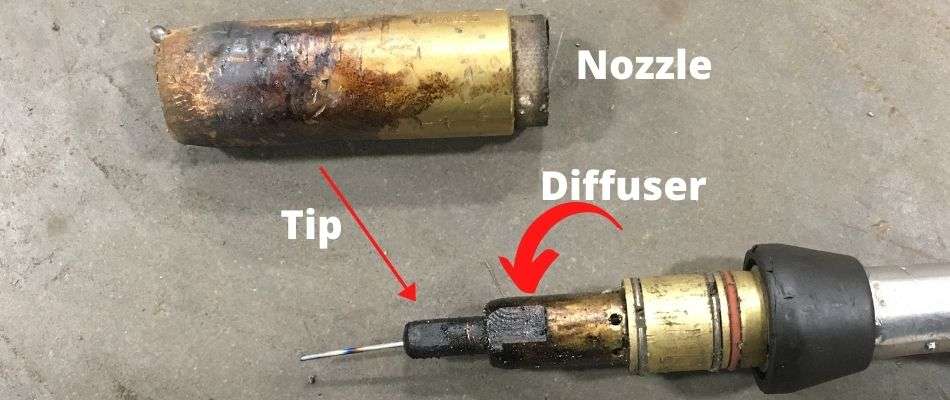

Once the wire passes all the way through the lead it will go through the welding gun. The liner actually goes all the way to the diffuser.

The diffuser is where the shielding gas comes into the nozzle. The diffuser is what also holds the tip.

From there the wire passes through the tip. The tip is what holds the welding wire straight and keeps it from moving all around.

6. The Arc

Finally, once the wire passes through the tip it mixes with the shielding gas and strikes an arc when the wire and metal connect.

This instantly creates an arc that melts the wire. When the wire melts it creates a hot molten puddle of metal. As the puddle moves forward it creates bead.

The bead is a pool of molten metal that bonds the two pieces of metal together.

What is Welding Wire Made Of

Now that you know how welding wire is used you also need to know what kind of welding wire you should uses when welding specific types of metals.

Related Article: To learn more about the type of welding wire you should use check out my complete guide here.

When it comes to welding wire you want to use the same type of wire as the material you are welding. So if you are welding mild steel then you want to use regular mild steel welding wire. If you are welding stainless steel then you want to use stainless steel wire, and if you weld aluminum then you want to weld with aluminum wire.

Finally, if you are welding mild steel you can get a few different types of wire here. You can get the copper-coated wire and non-coated wire. The copper-coated wire is used for keeping the wire from rusting and oxidizing. It also tends to be a bit cheaper than the uncoated.

Where Do You Get Welding Wire

Finally, you might be wondering where to get welding wire and there are a few places. The first place to go if you only need small rolls of wire is online. This works fine if you know the exact kind of wire and size. Online prices tend to be a bit cheaper as well.

The other place to try is local welding shops that sell wire. I’ve personally sold wire in the past to local farmers who need it but I find if you are buying a lot of wire then you’ll want to work with a local dealer.

If you buy enough you can work out deals with them. In fact we typically comparison shop multiple companies to see who can give us the best deal and if you buy a lot of welding wire you can do this as well.