How Much Should You Charge for Welding per Hour [Download]

How Much Should You Charge for Welding per Hour?

When it comes to running a welding business, you need to know what your hourly rate is. For a lot of people, they pull this number out of thin air because it sounds good. But how do you know the hourly rate you’re charging per hour is right?

The amount you charge per hour for a welding business is based on the overhead cost of your business minus the cost of steel. This would include employee wages, consumables like wire and gas, utilities, maintenance, insurance, company benefits, tools, and taxes divided by the total hours worked in a month.

Read this entire article to discover some common pricing areas many welding companies fail to include when charging customers. You may even find more room for profit in areas you previously didn’t consider charging for.

Side Note: I also included a free downloadable spreadsheet below along with a step by step guide.

How Much Should You Charge for Welding per Hour

When calculating your overhead costs for a welding business, you are effectively considering everything, from employee expenses to insurance.

The only thing excluded from daily operations with customers will be steel prices, which we will address later.

Employee Wages

Employee wages are a cost you must account for when taking on any new job. You will have to charge customers a very different amount if you bring in a team of 5 welders instead of just one.

Employee wages are the total amount paid to employees, including additional payments with benefits and bonuses. Employee wages can also vary based on skill levels and work experience.

Consumables

A welding business is like any other in that it needs certain consumables to stay functioning and to do custom work.

Consumables can range from welding gas and diffusers to specialized tips and nozzles for special case welding jobs.

It is important to keep an inventory of all of your consumables so you are not letting parts go missing that could potentially cost you more money in the future.

Utility’s

The power needed to run a welding business is often much higher than most other businesses because of the demands of the equipment.

With a wide array of safety equipment and welding machinery, you will need to run phase 3 power as opposed to 220 to get the most bang for your buck with power costs.

You may also need propane to heat your shop, and to pay for local utilities. Be sure to include all of these costs in your business.

Maintenance

It’s a part of any business where things break down and must be repaired. When you work in an industry like welding, where your tools keep your business running, maintaining their functioning is critical to business operations.

One thing to be mindful of with welding is that maintenance costs can often get very expensive if you are not careful. Getting a tow motor overhauled can easily cost upwards of $5000.

Insurance

Welding poses a lot of liabilities that are often required to be insured by most customers. The potential for accidents with the equipment means that insurance plays a critical role in any welding business.

Aside from liability insurance, you will likely also have to deal with property insurance for the building you work out of.

Special insurance policies are often needed when any welding equipment is involved. If something happens with the business, you may even have to cover insurance for partners or workers.

Company Benefits

Regarding workers, company benefits are a range of expenses you will have to face if you have some workers for your welding business.

Depending on the size of your business and the number of employees you have, most workers will expect health and life insurance policies to ensure they can take care of their needs if something comes up.

You may also want to look into benefits like 401k plans for long-term employees. Having benefits may cost you now, but the right ones can get good people to stick around.

Tools

Tools are essential to a welding business as they allow you to complete any work. Tools are plentiful and often expensive in a welding company, and all need to be accounted for.

Equipment like welders, tow motors, and vice grips must be accounted for when setting aside a budget.

Without the right tools, a welding business will be limited to which customers they can work with.

Taxes

The last thing to consider with your welding business is the inevitability of taxes. Every business needs to pay taxes, and welding businesses are no exception.

You will likely have to pay taxes for your property alongside any CAT and government-collected taxes.

How To Calculate Your Hourly Welding Rate

Calculating the rate per hour you want to charge can often be a hard number to pull out of thin air.

Thankfully, we have broken down the formula into five easy-to-follow steps to help you better understand how to calculate your hourly welding rate.

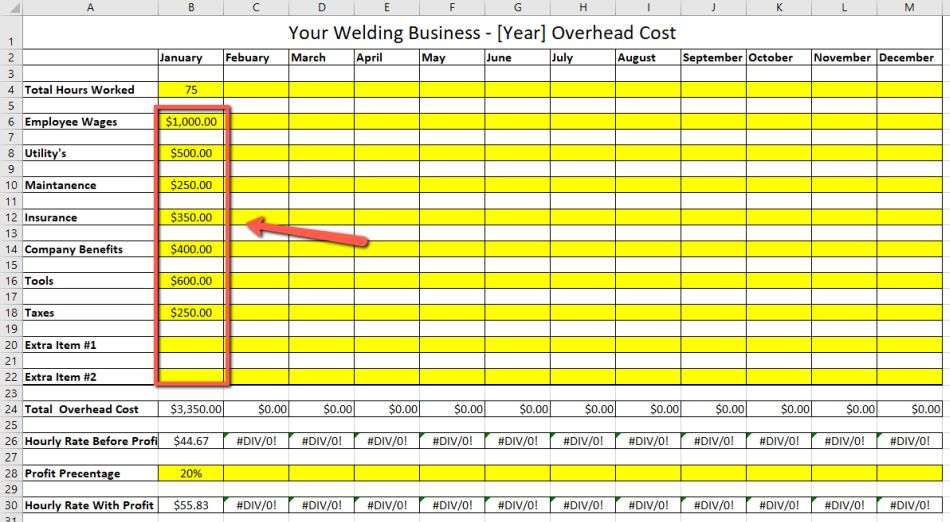

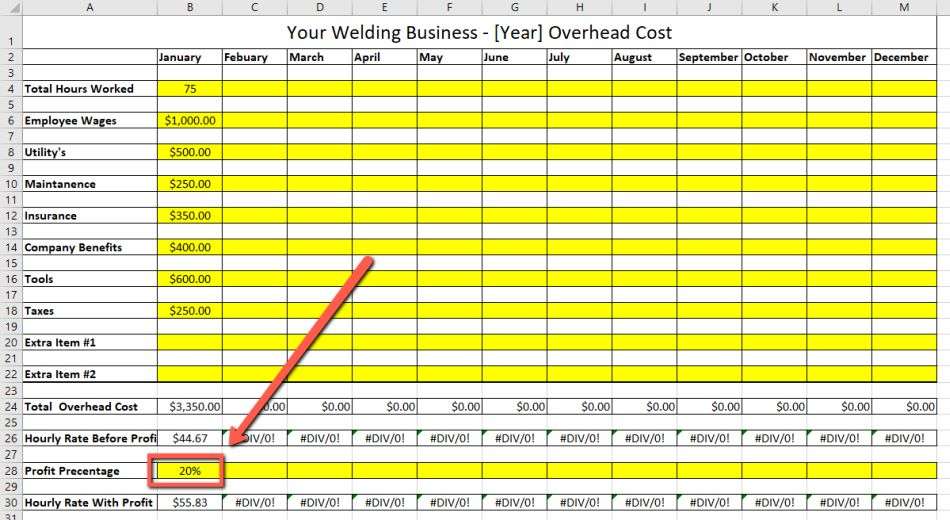

Resource: Here is a simple spreadsheet I created to help you figure out your hourly rate for your welding business.

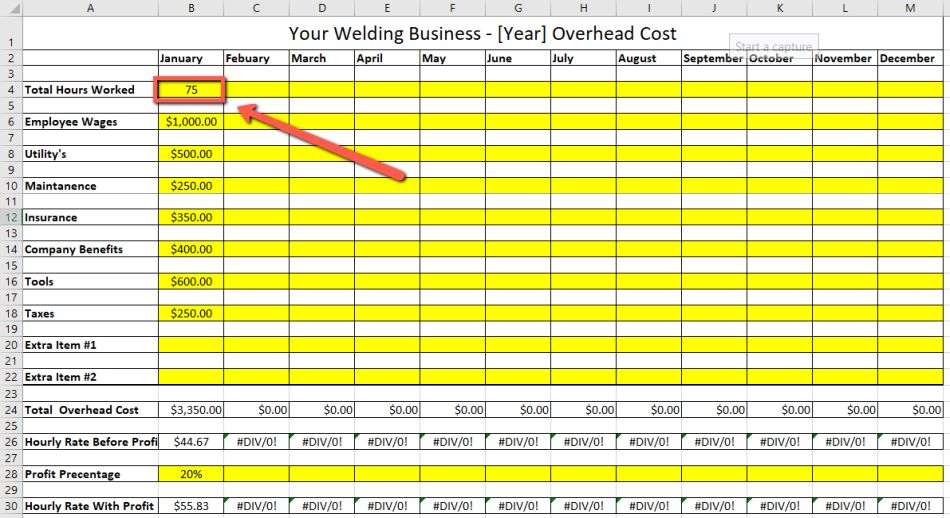

Step #1: Add up all the overhead costs you had for the last month

First, you will want to calculate the overhead costs you have from the past month.

This means going back and looking at all the categories we mentioned earlier to try and see how much you need to make to up that amount spent.

This will likely take some time, and maybe even an accountant, so using an Excel sheet will probably be the best way to calculate this data.

Step #2: Determine the total amount of hours worked by you and all your employees

Your next task is determining the number of hours worked by employees over the past month.

Depending on the number of employees you have, this could either be rather easy or somewhat difficult to calculate, depending on the number of people working for you.

Utilizing something like payroll software will give you a really easy picture to reference and use to determine how many hours were worked by your staff.

It is also important to remember and account for the hours you worked at the business.

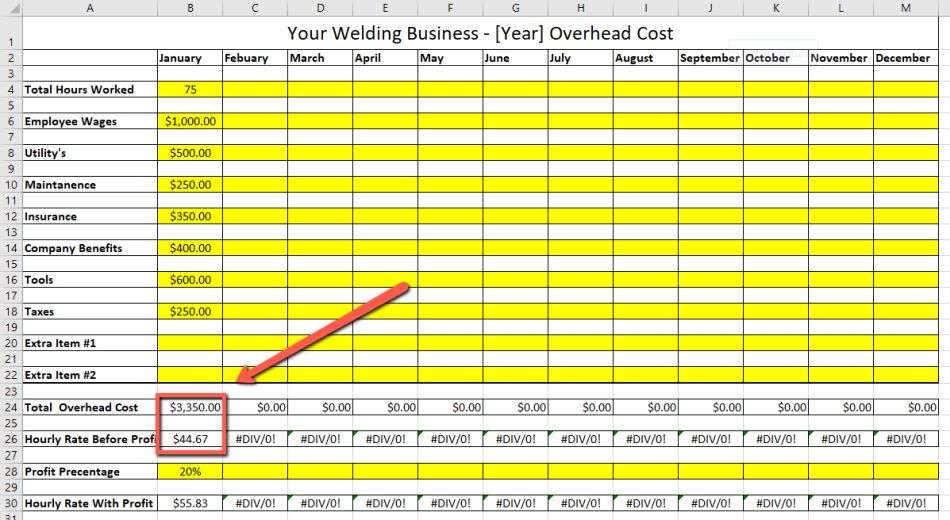

Step #3: Divide the amount of overhead by the number of hours your business did in the month

Determining the base price per hour you can charge to make up for any costs, you will want to divide your overhead amount by the number of hours worked in the past month.

This allows you to see how much you would have to charge for every hour of work to break even on the price it would cost to keep your business running simply.

For example, let’s say you had $57,000 in overhead for the past month. If you and all of your employees completed a total of 1500 hours of work, the value of your monthly overhead would be set at $38 an hour.

Step #4: Add a percentage for profit

To ensure you are making money for your business, you will want to add a percentage that accounts for the profit you hope to make.

Keeping this percentage number reasonable per hour is a good idea because the profit can increase substantially when you look at it in the bigger picture.

Using that same $38 per hour from the last idea, let’s add a 20% profit. You’ll divide that $38 by 0.80 to give you an hourly rate of $47.50 to give you a profit.

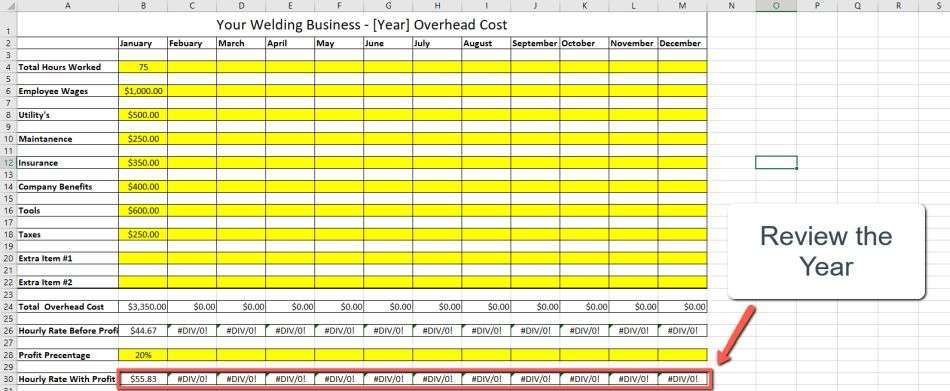

Step #5: Review the year

With a view of what each month looks like regarding expenses and profit, you will want to review your numbers in the 4th quarter of your yearly cycle.

When you look at all the data from the year, find the average of every month to see if you are making a profit. It may be hard to track your first year, but repeating this process frequently will make it second nature.

What is Not Covered in Your Hourly Welding Rate?

While most variables can be accounted for on an hourly basis of operation, certain outliers will need to be calculated after the hourly rate is established.

The most substantial spending in this category is the steel you used to get a job done as an extra cost.

With a job taking 10 hours to do at a rate of $48 per hour, let’s say you use $100 in steel. This would bring the total cost of the job to $1480. Understanding the costs of your welding business will allow you to keep things going.

Hello My name is JOSEPH i just want know how much to change tig welding per butts from 1″inch to 12 inch (cost)

Pelase help

All Regards