Can You Weld Cast Iron – A Helpful Guide for Beginners

As someone who’s been welding for 20 years I’ve found the toughest metal to weld has been cast iron. Cast iron does not weld like any other normal mild steel, stainless steel, or even iron. Cast iron is a very hard and brittle metal and has to be welded in a very specific way or it won’t hold.

Can you weld cast iron? Yes, it is possible to weld cast iron. First, you need to clean the area you plan to weld. Second, grind a groove for the weld. Third, preheat the metal to allow for better penetration. Fourth, use a stick welder with a Ferro-Nickel rod. Sixth do a root pass and fill the grove. Finally, let the weld cool very slowly to avoid cracking.

In the remainder of this article I’m going to share my exact 7 step process you can use to weld cast iron that will help it hold stronger and resist cracking after welding. Welding cast iron will take some practice and time to learn but with my complete seven step process you’ll be way more successful.

So let’s get started…

Can You Weld Cast Iron?

Yes, you absolutely can weld cast iron, but you need to do it in a very specific way. You also need to do it in a very specific order of steps to ensure its quality. Some of the reasons you cannot treat cast iron the same as other metals is:

- Cast iron is extremely hard and brittle

- Its mixture of metals is unique to itself

- It is sensitive to sudden changes from hot to cold

- While other ways will work, “it” prefers one method over the others

One thing to keep in mind when considering welding cast iron, is that you cannot just weld it together with any welder and expect it to hold.

There is one method that works better than others, however, when following the proper steps and procedures, other methods will also work. Here is a shortlist of some of the ways to weld cast iron:

- In most cases a stick welder will be the best option

- MIG can work but not always the best option

- Brazing or bronze welding is a viable option

- TIG welding will also work to weld cast iron

This does not mean that you can just grab any one of these options and jump right into welding your cast iron. You need to follow a certain set of steps in order for the whole process to work correctly.

Directly below, we will discuss these very important steps in further detail.

How to Weld Cast Iron

Welding cast iron is not harder than welding any other kind of metal, however there are some important things to remember and some important steps to take when starting out.

Failure to follow in any one of the 7 steps could result in the failure of your weld, and possibly, it could ruin the cast iron for future welding.

If this happens, you will have to remove even more material to make the weld. There will be some cases that this is not a possibility. So, to ensure your success every time, follow these 7 simple, yet important, steps.

What You Need to Know Before Welding Cast Iron

Here are the 7 important steps that you need to follow when welding cast iron.

Once you properly learn these steps, you can successfully weld cast iron and teach your employees how to properly do so.

After doing this the first time, you will quickly find out that it certainly is no harder than welding any other kind of metal.

#1 Clean the area you plan to weld

This is an important step in any kind of welding, as a dirty base will quickly contaminant the whole weld, causing it to fail at some point.

This is twice as important when welding cast iron, as the chemical make-up of the cast iron is quite different than other metals.

Make sure to follow this simple guide to having a good, clean place to start welding:

- The material should be at room temp

- You should use a grinder and/or sandpaper

- Use a degreasing agent

- Let dry completely

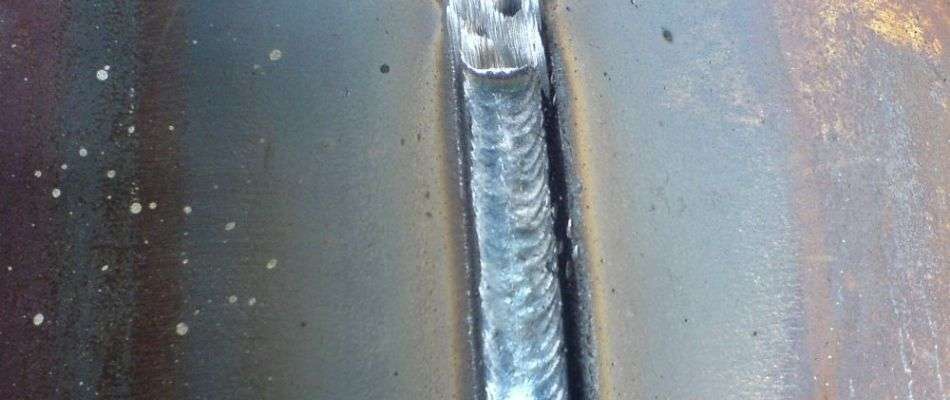

#2 Grind a U Groove in the metal

With any kind of welding, you need to remove a certain amount of the surrounding steel in order to get the proper penetration for the weld to properly bond.

Traditionally, this is a V-style cut for conventional welding, however, when welding cast iron, you want to use the wider U-style groove.

If you prefer or plan to do a lot of cast iron welding, there are special grinding wheels available to cut that specific channel needed for the cast iron. Remember these rules when cutting the groove:

- The groove should be 45-60 degrees

- It should go 80-90% of the way through the material

- After cutting the groove, make sure to clean the area again

#3 Preheat the metal to around 500 to 1200 degrees

This is a great idea to speed up the welding process for any metal. However, it is critical when welding cast iron. If you do not do this, the cast iron will heat up in a way that can cause the weld to fail. Always remember:

- This is very important when welding cast iron

- Without pre-heating, the weld will not hold

- Begin welding immediately after pre-heating

#4 Use a stick welder with Ferro-Nickel or Pure Nickel

When you weld cast iron, you must use the proper welding rod. If you do not, not only will it not properly adhere to the cast iron, but it cost a dangerous environment with sparks and possibly molten metal that would not otherwise be there. Never forget:

- This type of rod is critical to the success

- Any other rod will not bind to the metal

#5 Do a light root pass to establish a bond

This is a standard operating procedure for welding any kind of metal. However, with some other methods and metals, this is not required when welding say, a crack.

With cast iron, this is just as important as if you were welding two separate pieces together. Never skip this step when welding cast iron, and always remember:

- Standard procedure for any welding

- Critical to the success of the weld

- Must be done correctly

#6 Do secondary passes but do not overheat the base metal.

This is critical when welding cast iron as if the metal is heated above 1200 degrees, it can change the internal structure.

If done correctly, there is nothing to worry about. One way you can guarantee this is to have an infrared thermometer that you can constantly read the external temperature of the cast iron as you are welding. Take into consideration:

- Do not let the metal heat above 1200 degrees at any time

- This will change the structure of the metal

- It will also cause the weld to fail

#7 Once welded let it cool at room temp very slowly.

While this is used in other methods and for different end results, it will absolutely ruin the cast iron weld.

It will cause cracks to form, likely coming from where you have just welded, if not forming in other areas. This will be detrimental in the structural integrity of the cast iron.

- The cast iron can crack if it cools down too quickly

- This will cause the weld to fail

- It can cause the metal to be ruined for future welding

Can Cast Iron Crack When Welded

Yes, if the weld cools to quickly it can cause the metal to crack.

- Do not quench the metal with water or oil to cool it down.

- Cooling down too fast will cause to crack

- Let it cool at room temperature.

- If in a cold area put it someplace where it can cool slowly.

After compiling the 7 steps needed to weld cast iron, it is clear that welding cast iron can be done with little problem, as long as you follow the steps we have outlined.

If you follow these simple steps, you will always have success when welding cast iron. Once you do the whole process once or twice, you will find the steps to be second nature.

Once you can do these things successfully, you can teach others, possibly your employees, to also be successful cast iron welders. The following websites can offer additional resources and information that could help you in your quest to weld cast iron.

Don’t let the misconception that cast iron cannot be welded stop you from trying, as long as you follow the steps, you will have success every time.