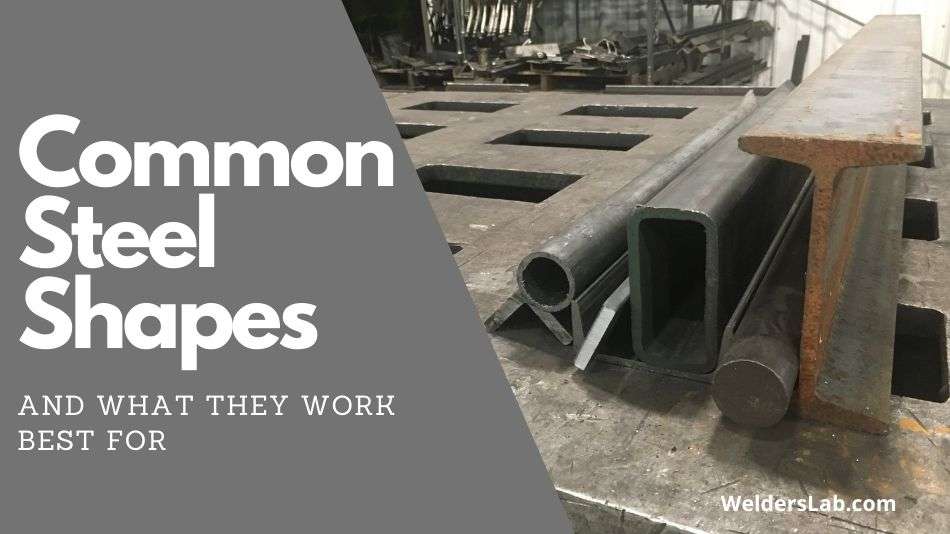

7 Most Common Steel Shapes and What They Work For

Over the years I’ve used a lot of different various types of steel and different shapes of steel to be more specific depending on the job and what I needed it for. Whether I’m building gates, a skid loader bucket, or even a fire ring stand each project requires different types of steel.

The 7 most common types of steel are:

- Rod

- Flat Bar

- Sheet Metal

- Angle Iron

- Channel Iron

- I Beam

- Tubing – Pipe, Square, and Rectangular

From the incredibly versatile flat bar all the way to the I Beam that has helped build the world’s tallest buildings, there is a steel structure out there for just about everything.

Each piece of steel tells a unique story and understanding what makes each style of steel shape unique and how it is intended to be used is essential.

Once you learn more about these 7 common steel shapes, you will have a much greater understanding and appreciation for how much the shape of a piece of steel can effect its uses.

We will help you understand what the steel structures are used for, what their sizes usually look like, as well as point out a few interesting facts about where you can see the structures shape our world.

7 Common Types of Steel Structures

Flat Bar

As the name suggests, flat bar steel is quite literally just a flat bar of steel that is incredibly versatile. Flat bar steel is very easy to shape and cut to size which is why it is so widely used in areas like welding or drilling to help during construction when a frame needs to be given some form of shape.

Flat bar is often used as a basic building support material where they are great for implementing support braces for ductwork areas.

You can find flat bar steel in any number of sizes ranging from quarter inch all the way to 12” wide by 20’ long segments. The size versatility of flat steel is what allows it to be used so widely when tasks like punching or bending are utilized.

Flat bars are readily formed to the shapes necessary for added support when a construction project needs some extra reinforcement.

A unique place that you can see flat bar steel used frequently is in the creation of industrial statures that benefit from the easily molded steel.

Rod

Following the same easy to follow the naming system as the flat bar steel, rod steel is long and thin rods that are forged from steel.

This steel is unique in that it has been created in a way that ensures it has a tight tolerance diameter and is often tempered before being shaped further.

The shape of rod steel is most often seed with a cylindrical shape, but there are also variations that utilize a square design. Regardless of the shape, rod steel is great when something needs reinforcement or protection.

You can find rod steel in a wide array of sizes from quarter inch up to 20” round for more serious needs. If you are looking to keep something away from something else, steel rods are going to be a great way to get the job done.

If you ever see bars placed over a window for protection, that I likely a construction that utilized rod steel. The added durability that is found through creating rod steel is what makes it so ideal when you are looking to reinforce an area or use it for protective purposes.

Sheet Metal

Sheet metal is one of the variation of steel that most people are easy to associate with. Considering how sheet metal made of steel is often found in just about anything with metal in it, you don’t have to look hard for a use for sheet metal.

You can look to alloy steel for a cheap and effective sheet metal solution that provides a basic level of strength and protection without being too expensive.

You can then get more robust options like stainless steels that are fabricated differently are going to give you a stronger sheet of metal.

You can find sheet metal sizes commonly looking like 4’x8’ or up t0 5’x10’ if you need more material.

One of the many benefits of sheet metal is the fact that it can be used to cut out very unique and odd shapes that would otherwise take much longer to fabricate using other methods.

Sheet metal is used commonly for punching, bending, and forming thanks to its ability to form to nearly any shape necessary.

Depending on what the sheet metal is being used for, you can create with various metal qualities that affect how strong or flexible it is based on your needs.

Tubing– Box, Square, and Round Tubing

Steel tubing has come a long way since it’s first inception and has evolved into a very capable form of steel for modern manufacturing.

You can find tubing in box, squared, and round shapes that allow it to be used for various tasks. The ability to create it with different alloys also means it can be used in areas where either added strength or resistance is needed.

In recent years, the steel tube has seen widespread use in the automotive industry where it is used to create the structural elements of many vehicles.

Square tubing commonly comes in a 2″X 2″’ size, box tubing comes in a 2″ x 4″ size, and round tubing comes in sizes that are measured using pipe sizes tubing as a reference and can be found in sizes like 1 ½ PST.

So many shapes and sizes of tubing allows it to be used in anything from a car to scaffolding. There are also variations of the steel that are welded together or seamless for different uses.

Angle Iron

When you need added structural integrity for a given object, angle iron is going to give you just what you are looking for.

This steel formation is normally found in a traditional L shape that is very commonly used to support buildings and free-standing structures.

You can see angle iron being used to support massive bridge elements all the way down to keeping shelves upright when loaded with items. The benefits of structural integrity provided by angle iron make it great to add to anything that you feel could use some extra support.

You can find these units in either equal lengths like 1” x1” or unequal lengths like 1” x2” depending on what kind of support you are looking for.

Angle steel can get various metal treatments to make it better suited for certain environments or uses. For example, gate integrity can be improved by adding an angle iron to the top to prevent any bending on the surface of the gate.

C Channel

The C Channel, also known as the structural channel, lives up to its name with its C shape and intention to add structural support wherever necessary.

The very distinctive shape of this steel makes it suited for situations where bracing is needed in a very specific way.

The C Channel support from steel is very popular in both automotive and marine construction for its ability to give necessary support without any additional weight.

C channel is unique from other common support beam styles in that it as it only has flanges on one side of the web.

Most channel measurements are going to use the depth of the channel itself and the weight in the foot of the given channel. In many buildings, C channel steel is used for support elements and can also be found in many stair casings.

Overall, the C Channel is not the most popular of beams, but it certainly has its beneficial uses.

I Beam

Last bust certainly not least, we have the loved and trusted I Beam. These are probably one of the most well-known steel structures as they can be seen as the foundation and core of nearly every building.

I beams are regarded for being one of the best ways to reinforce critical areas of a building or structure as they are able to displace a load over their area more effectively than other beam options.

Most construction jobs that need a structural area to have maximum support will use I beams as either supporting trusses or the main framework of a building itself.

With its use in large scale products, you can very easily find I Beams in 20, 40, and 50-foot options. You can also find I beam with different width flanges when they are needed to bear extra sensitive loads or are used for foundational support.

The I shape is likely so popular because it is able to provide excellent structural support without wasting any unnecessary steel in the process.

This makes the steel lighter than larger beam styles while still offering great support. The ability to support unique loads from various positions makes these the beam of choice for most construction projects on larger scales.