How to Use a MIG Welder Without Gas

A few years ago I learned that I could use a MIG welder without gas and in this article I want to share how I learned to do this.

How do you use a MIG welder without gas? Instead of using a gas to protect your weld you can use flux core which has flux inside of a hollow wire and when melted shields the weld similar to a shielding gas.

However flux core is a bit of a different way to MIG weld their are a few things you should know for go any further.

Welding Without Gas – How It Works

Flux core is also known as Flux Core Arc Welding, FCAW for short works without the use of a shielding gas.

In order to weld without gas, you will need what it called flux core welding wire. Unlike your typical welding wire which is just a solid wire flux core is a tubular wire that has flux in the center of it.

Flux wire is a consumable wire that works like almost any other welding wire except when it arcs with the base metal it will melt the wire and begin burning the flux at the core of it.

Did You Know: Flux Core uses a direct current just like your car battery.

Once this happens the flux will produce a gas cloud around the weld and protect it from oxygen around it.

When it comes down to it their are two types of flux core processes.

- FCAW-S – This is known as Flux Core Arc Welding Self Shielded which is the most typical flux core method that I just mentioned.

- FCAW-G – Is known as Flux Core Arc Welding Gas Shielded which uses a flux wire but also requires an extra shielded gas such as CO2 or Argon and CO2.

Either method will create a similar weld but since the wire contains flux it will also produce slag on top of the weld which may have to be removed using a chipping hammer or something similar.

Finally, in order to use flux

This is done to protect the flux core wire from getting smashed as it moves through the wire feeder.

Quick Tip: You’ll want to avoid over tightening the feed rollers as this will damage the flux core wire and may not produce the desired weld you are looking for.

However the real question you might be asking yourself is can weld with out a shielding gas or flux core at all?

Can You MIG Weld Without a Shielding Gas or Flux Core

The short answer here is no.

No matter what you weld whether it’s mild steel, stainless steel, aluminum or some other exotic metal you will always need some sort of shielding gas or flux to protect the weld.

Why is this you might ask?

If the weld is not sheilded from the outside air it will oxidize and create a weld with a bunch of pits and holes in it. The weld will not look very good but most importantly the wire will not create a strong hold with the base metal.

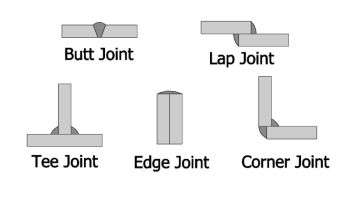

This could result is a week joint that could break very easily if it goes under a lot of pressure.

So for example, if you attempt to weld the frame of a motorcycle without any shielding gas or flux there is a very good chance your joint will break which could result in a major accident.

So make sure you’re always using a sheilding gas or flux core when welding with MIG.

The Advantages of Flux Core

So now that we have a clear understanding of how to weld without gas using flux core you might be wondering what would some of the advantages be to using flux over regular sheilding gas.

#1 You won’t need to carry a cylinder of gas

To start you won’t have to worry about carrying a cylinder of gas around with your welder. While smaller cyliders of gas are

Most bigger cylinders weigh over

If the tank isn’t properly fastened it could crack the valve off resulting in a bad accident.

Finally, not having to buy a tank of gas to weld with will save in cost as well.

#2 Works better welding outdoors

Next welding with flux core works better in outdoor situations versus having a tank.

Since the flux burns only when the wire melts and arcs with the metal it’s more likely it will

#3 Can handle a dirty surface

Finally, like stick welding flux core welding also does good at welding surfaces that may be dirty or even rusty.

Your normal MIG wire will typically need a clean surface and will likely not work as well on rust.

When to Use Flux Core Over Gas

So when should you use flux core wire over gas? Here are a few suggestions.

Working Outside – If you have to do a lot of work outside welding then flux core makes perfect sense here. When you’re outside the weather is hard to control.

If it’s windy outside then flux core will help keep the shielding gas from the gas closer.

A good example is a farmer. A lot of times farmers have to fix things outside in the elements and don’t always have a place inside. They may have to repair old gates or repair the frame on a busted wagon int he field.

Working on Dirty Surfaces – If you’re also someone who has to weld together something that doesn’t have a cleans surface then flux core would be a great option here.

As I mentioned earlier flux will bond with dirtier surfaces better than using your typical welding wire and gas.

A good example of this is someone who has weld something rusty like an old

What Kind of Flux Core Wire Should I Use

So now that you’ve got a better understanding of flux core wire and welding without a gas the last thing you need to think about is the kind of wire you should have.

They make flux core to weld different types of steel from you normal mild steel, aluminum, and stainless steel. They type of wire you use should be the same type of material you plan to weld.

For example, if you plan to weld stainless steel then you should use a stainless steel flux wire.

The only thing I should mention is that you will have to adjust your wire speed and voltage settings since flux core

Related Questions

#1 Is flux core stronger than using a gas? Flux core will burn hotter with flux core but that doesn’t nessesaraly mean it’s a stronger weld. The strength of the weld all depends on how well the filler metal penetrates to the base material and the strength of the joint created.

#2 Is flux core easier to weld than using gas? Of the flux core I’ve welded I’ve found using MIG with a regular

#3 Do you push or pull flux core welding? Like almost all welds it is better to push your weld than pull it. The weld will fill in better, bond with the material better and overall look much more aesthetically pleasing.

So now that you’ve had a chance to learn a little bit more about how welding without gas works and the methods are you considering using flux core to weld with?

Have you welded without gas? Share your thoughts on this in the comments below.