How Do You Prepare Metal for Welding?

You’re all psyched up for a welding job. Maybe it’s your first one or maybe you’re a seasoned welder and you’re just really excited for the upcoming job. You grab your gear and your tools and you hit the road to your welding location.

When you arrive, the piece you are going to be welding is greasy and coated in grime. You notice some rust flaking and your excitement quickly turns into an eye roll.

One of the first things you learn as a welder is that your surface preparation is a major part of your welding success. You have to prep your surface appropriately or you may run into all sorts of issues.

Preparing your welding surface is essential and you should understand how to work with and prepare a multitude of surface issues.

How exactly do you prepare metal for welding? Depending on the metal if there is any grease or oil, it should be removed with a rag and wiped down clean. You will also want to remove any rust or mill scale with an angle grinder as this could cause an improper ground and not allow the weld to penetrate the base metal.

In this guide, we will cover how to prepare metal for welding. We will give you a basic overview of preparation and then take you through some specific situations you could run into as well as sharing some tools that could be helpful for you in the process.

Keep reading to learn the most important knowledge about preparing surfaces for welding.

How to Prepare Metal for Welding – A Complete Guide

Not to give you a lecture but preparing your work surface is perhaps one of the most important steps to take in any welding process.

Don’t skip this step! In your gear and tool bag, you should have appropriate tools and accessories to face whatever your surface may throw at you.

Things like oil, grease, rust, corrosion, grime, or anything else will make a difference when you weld. So just be proactive and assess these scenarios before you begin.

Prepare the surface. Welding is not just about the heat and the welding gear, it’s about the job from start to finish and the start includes preparation.

How to Prepare the Welding Surface

To prepare your surface, you need to simply start with the basic approach of cleaning your welding surface. Wipe down your surface using something like low VOC PRE or even acetone.

These chemicals can help to remove oils, stains, grease, and other residues so you don’t have to worry about any of that residue negatively affecting your weld.

Side Note: Be careful if you use any flammable liquid on the surface of the metal. Do not operate your welder around these kinds of flammable liquids as it could cause a fire.

Even brand new metal that has never been welded should be cleaned because it most likely has some sort of coating, such as mill scale on it that reduces the risk of rust and so on.

Don’t ever take for granted a clean-looking piece of metal. Just wipe them all down as a best practice.

The various types of welding require different elements of how clean or perfect your surface should be.

For example, MIG welding doesn’t have to have a completely clean surface although you should still go through the preparation process anyways.

In terms of how to prep metal for welding, it typically requires much more than just wiping down the metal.

Most likely, you will need to follow an entire process of first cleaning the metal followed by processes that include brushing, grinding, sanding, and/or blasting.

If your metal is properly cleaned and prepared, you are more likely to experience the best weld possible when you get to work on the welding part of the job.

Here’s a general step-by-step illustration of how you should work through the metal preparation process.

- Wipe down surface with acetone or appropriate cleaner.

- Work out impurities, rust, or other variations that could affect the weld. These tools may help.

- Wire brush

- Angle grinder

- Plasma cutter

- Abrasive blasting

- Add finishing touches to clean up the surface – sanding or wiping away residue.

- Complete a final wipe down with appropriate cleaner to clear away any loosened debris.

3 Different Situations You May Deal with When Cleaning Metal

I think you know what I’m going to say here. Not all surfaces will be the same. Some surfaces will present unique challenges while others will be simple to clean and prepare.

Here are the most common situations you are going to come up against in welding prep.

- Oily or greasy surfaces

- Rusty or abrasive surfaces

- Painted surfaces

#1 Oily or Greasy Surfaces

If you’re working with a surface that is simply oily or greasy and doesn’t have any rust, corrosion, or other residues your preparation process shouldn’t be too challenging.

You will need some cleaner, low VOC PRE or acetone work best. You will also need either steel wool or a wire brush for the cleaning process.

To clean up oily or greasy surfaces simply use the appropriate cleaner as well as your wire brush or wire steel.

You can either first go over the surface with the steel brush and then wipe down the surface with cleaner or you can use some combination. We recommend using the wire brush and then the cleaner for the best results.

On a side note, do not cross-contaminate your brushes with various metals. Keep separate brushes for separate metals to avoid other issues or use something you can toss after each use.

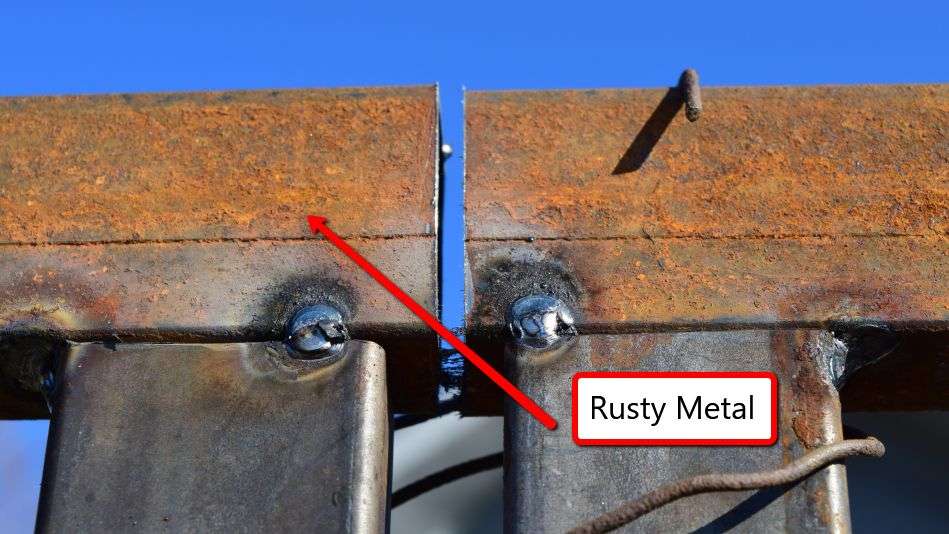

#2 Rusty or Abrasive Surfaces

In terms of how to prepare rusty metal for welding, you need to keep in mind that you must first remove the rust or any abrasive material on the metal and then clean the metal accordingly to remove any residue.

Let’s be clear, you should never have rust in your weld zone. That means it’s imperative to take care of the rust or any other abrasive materials prior to welding. To remove rust, you can use sandpaper, steel brush, or an angle grinder. These tools help to remove the rust and other coatings so you can move on.

Once you’ve cleared the surface of rust, you can then clean it before proceeding.

#3 Painted Metal

One final tip is to also remove any paint that is on the metal. When it comes to paint it can cause all kinds of issues with your weld.

First it will produce toxic fumes that are not going to be safe to inhale.

Second it will not allow your weld to penetrate the metal as good as a properly clean surface since it’ll have to burn through the metal first.

Finally, if you have paint on the surface of the metal you may not even be able to strike an arc with the welder as the paint will act as a conductor and not allow the welder to make a complete circuit to start the weld.

So not only will you have to grind the surface of the area you are going to weld but you’ll have to grind a spot off to place the ground clamp on.

2 Tools That Might Help Clean the Welding Surface

You’ve already seen us mention various tools to help you in the cleaning process.

There are two specific tools that we recommend you invest in and keep on hand for cleaning your welding surfaces.

- Wire Brush

- Angle Grinder

These two tools should be able to appropriately tackle just about any welding surface for preparation.

You might also see suggestions for things like steel wool, plasma cutters, sandpaper, or even blasting. These are other suitable options but not a requirement.

Wire Brush

You can accomplish a lot with a wire brush. Wire brushes scrape away any rust or other coatings that will be in the way of your welding requirements. Steel wool works quite similarly to a wire brush but wire brushes tend to be easier to control and work with.

Remember not to contaminate surfaces. This is especially important if you work with various types of steel or aluminum. You can label your brushes for specific surfaces if that is what works best.

Whatever you do, don’t use the same wire brush on different types of surfaces as you’re more likely to contaminate the area and cause yourself bigger problems.

Angle Grinder

Your angle grinder makes a great power tool option for cleaning your surfaces.

You might even combine the angle grinder with a flap disc, depending on your surface.

When you use an angle grinder be mindful of the speed, pressure, and your angle grinder attachments.

Be sure to use the appropriate settings and utensils for the appropriate surfaces.

Do You ALWAYS Have to Clean Metal Before Welding?

The short answer to this question is yes. The thing is, cleaning your surface is what will give you a quality weld.

MIG welding doesn’t require as clean of a surface but with TIG welding, you need a spotless surface.

If you want a good penetration or high-quality weld, always clean your surface.

If you’re fixing something out on the family farm or working with a non-load bearing item than you can potentially get away with not cleaning the surface, just know it may not be the best weld in the end.

Conclusion

Proper preparation of your welding surface is perhaps one of the most important elements of the welding job.

If you don’t clean or prepare your surface appropriately, you’re like to get frustrated or be disappointed with the quality of your weld.

When it comes down to it, if you don’t prepare your metal properly prior to welding, your metal is less likely to penetrate and your weld is more likely to end up with imperfections.

Additionally, it can lead to a safety issue because your weld may not be stable or reliable.