Is Soldering as Strong as Welding and When to Use It

Over the years I’ve welded all kinds of stuff from hog gates, trailers, and even metal trees for the Columbus Zoo. Yes, you heard that right. However, when it comes to something like soldering my experience is a bit lacking. The question is if you can solder something and hold just as well as welding something?

Solder melts at around 360 degrees Fahrenheit, unlike welding which melts at around 10,000 degrees Fahrenheit. As a result, the solder does not penetrate like a weld which will melt into the steel causing it to bind itself to another piece of metal.

Now, this doesn’t mean soldering doesn’t work, it actually works great for certain situations that welding wouldn’t. So in the rest of this article, I’m going to share the difference between the two and when to use them.

Is Soldering as Strong as a Weld?

Soldering is not going to hold like a weld would. There are a lot of reasons for this from the temperature, the type of metal that is used, and the process that are used are completely different.

Temperature

The first major difference between soldering and welding is the temperature difference. According to TWI-Global, the optimal temperature to solder at is around 600 degrees Fahrenheit.

When comparing this to welding it can range in temperatures around 10,000 degrees Fahrenheit. To give you some perspective the surface of the sun is around 9,941 degrees Fahrenheit.

This is hot enough to melt metal and fuse it together with another piece of metal.

Type of Metal Used

Next, the metals used in soldering and welding are very different from each other. Soldering uses a mixture of tin and lead. This metal is used for everything you solder.

However, welding uses the same metal that you welding on. For example, if you’re welding mild steel then you would use a steel wire, if you were welding stainless steel then you would weld with stainless steel wire, and if you would weld aluminum then you would use an aluminum wire.

Process

Finally, you have the process that soldering and welding use and they are very different.

To start, soldering uses a hot iron that melts the filler metal. As the metal drips on the surface of the metal it hardens creating a joint. A soldered joint will typically just lay on top of the metal to form a joint.

When you’re soldering it also doesn’t require a positive and negative ground, unlike welding which does. You can learn more about how the welding process works in this article.

With welding, it creates an arc the instant the filler metal comes in contact with the base metal. From there it creates a pool of metal at an extreme heat of 10,000 degrees Fahrenheit causing the filler metal and base metal to fuse together.

At this heat is will form a solid joint that can be many times stronger than a soldered joint.

When Does It Make Sense to Solder

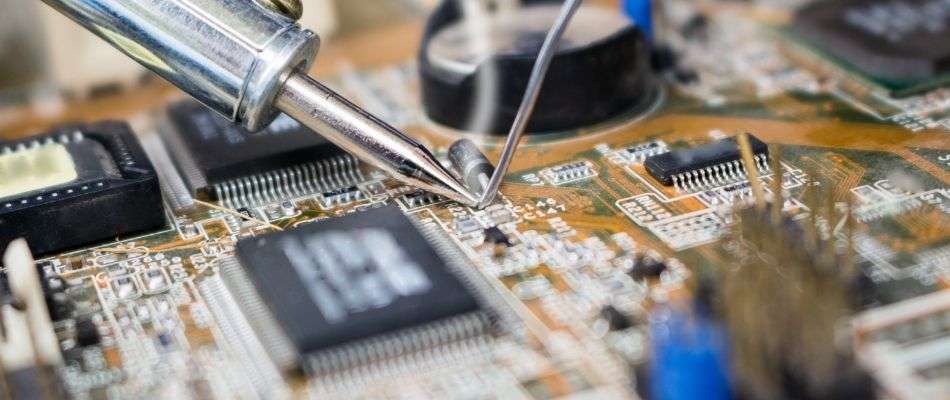

Soldering has many uses from soldering wire splices, circuit boards, plumbing, jewelry, and a whole lot more. So when does it make sense to use soldering vs welding?

Materials

To start you have to consider what kind of metals work best for soldering. Here is a shortlist of metals you can solder.

- Tin

- Gold

- Silver

- Cadmium

- Palladium

- Rhodium

- Copper

- Bronze

- Lead

- Nickel

- Berylium

If you are trying to join any of these materials together then soldering is your best option. You can also weld other metals like low carbon steel or zinc but they don’t hold as well as the list mentioned above.

Electrical

Soldering is the best option when it comes to anything electrical. Solder is a great conductor of electricity. On top of that, it works great at getting in those tiny places to bond wires together.

If you have a circuit board that you need to reattach a wire to or a wiring harness that needs to be fixed soldering it is your best option.

No Weldable Materials

Solder also works great when it’s something that is not a weldable material. For example, you wouldn’t weld two copper water lines together. Cooper is a very soft metal and the welder would just burn right through it.

The same goes for electrical stuff link circuit boards and wiring. Most wire is made of copper and it would disintegrate if you were to try and weld it.

Jewelry

Solder also works great for making or fixing jewelry. Again you wouldn’t try to weld jewelry together as it would likely melt the whole thing.

The great thing about solder is that it can attach itself to the metal without deforming the other piece of metal.

When Does It Make Sense to Weld

When it comes to welding it has a lot of great uses from welding structural beams, creating solid joints to hold the metal in place, to artistic projects.

Material

First off, if you are trying to join two pieces of mild steel together then a welder is going to be your best option. Here are just a few materials you can weld together?

- Mild steel – a36

- Harden steels – AR400

- Stainless Steel – 304 grade

- Aluminum

All of these materials can be welded.

Strength

Welding also works best if you want to have strength in it. For example, you wouldn’t want to solder a skyscraper together. Welding joints will penetrate the metal deeper and form a stronger bond.

If you want something to hold in a permanent position and support things then welding is the best way to go.

A few years ago I build a bunch of shelves for my basement and in that case welding is the best option to hold it together.

Colors

The other great thing about welding is that it can make some very beautiful colors when using certain levels of heat. This look can be very decorative and appealing to the eye.

This can be hard to do but when done it the right looks great. This is something you just can’t do with solder.

Final Thoughts…

So if you are trying to figure out if solder is strong enough to hold or if you should use a welder then use this article as a guide to help you get started.