What Gas Do You Use with a MIG Welder – A Helpful Guide

One of the very first things I had to learn when I was first learning to weld was what gas I should use when I’m welding. After all, there are several different types of gases you can use for MIG welders.

What gas do you use with a MIG welder? Depending on the type of metal you are welding you can use a variety of different welding gases from straight CO2, to a mixed gas such as Argon and CO2. In other cases, you can use straight Argon or even a mixture of 3 gases called a trimix.

In this complete helpful guide, I’m going to share all the different types of gases you could use to MIG weld with what they are used for and the pros and cons of each.

The 3 Basic Types of Gases

When it comes down to it there are 3 types of gases that you can use to MIG weld with. I’ve found these to be the most commonly used gases and each one

When it comes down to it in some cases you will only need just one gas to weld with. In other cases, you’ll need a mixture of gases to weld with. The gas and the mixture you use all depends on a few factors.

#1 What do you plan to weld? The gas you use depends a lot on what metal you are welding. If you are welding aluminum you’ll want a certain type of gas. If you are welding stainless steel you’ll likely want something completely different.

#2 How strong do you want the weld to be? Second, if the weld needs to be a strong weld then you’ll likely want a gas that will help you penetrate deeper creating a strong joint with the base metal.

#3 What do you want the weld to look like? The final thing to consider about the gas you are using is what does the weld look like when you are done. If you are looking for a more aesthetically pleasing weld then you’ll want to use the right gas that will give you that look.

So what are the basic types of welding gas?

- CO2 – (Carbon Dioxide)

- Argon

- Helium

When it comes down to it most welding gases are made up either one of these or a mixture of these to help you get the weld you are looking for.

Here are the basic types of mixtures you will find with MIG welding.

- 75% Argon and 25% CO2

- 85% Argon and 15% CO2

- 90% Argon and 10% CO2

- Argon CO2 and Helium (Tri-Mix)

In the rest of this article, I’m going to cover what each of these gases is, what they are used for and the pros and cons of each one.

What About Flux Core

Now one thing you might be thinking about is flux core and this article isn’t going cover anything on that topic because while it does act as a shielding gas when burned it doesn’t fall under the type of gases covered in this article.

Rather flux core is a type of welding wire that takes the place of using a shielding gas and is not a gas. If you would like to learn more about flux core check out this article here.

CO2 – Carbon Dioxide

CO2 is one of the most basic gases that you can use for MIG welding. However, CO2 is not as commonly used anymore like the mixed gases I’m about to get into.

However there are some things CO2 is good for, some things its not.

What is CO2 used for? To start CO2 is great for welds that aren’t going to be seen as much. I like this gas for welding stuff that might go on the underside of a car frame.

I also like it for around the farm because it penetrates deep and in most cases, I don’t need my welds to look the best. With CO2 my weld will look a little rougher and that’s ok.

So I find this type of gas to work best in a situation was things don’t need to look perfect and you want deep penetration.

The Pros of CO2

- Deepest Penetration – CO2 will give you the deepest and broadest penetration available. It will burn the hottest of all the gases.

- More Economical – Of all the gases you can buy CO2 is going to be your cheapest option. Mixed gases will almost always cost more.

Cons of CO2

- Not Good On Thinner Metals – Since C02 burns so hot it doesn’t work the best on really thin metals.

- Gives More Spatter – CO2 will give off more spatter. Spatter is the by-product that comes off the weld as you lay the bead.

- Bad Aesthetics – When it comes down to it CO2 does not look the best. If you want a really clean looking weld then this may not be the gas you’ll want to use.

75/25 Gas Mixture

The next gases I’m about to get into are all mixed gases and the first one is called C25. This gas is a mixture of 75% Argon and 25% CO2.

This is a typical gas that a home hobbyist would use because it typically gives a better-looking weld.

What is 75/25 used for? C25 is a great gas those who want a cleaner looking weld. The weld will typically look a little broader on top but as the weld penetrates deeper into the base metal it tends to narrow up.

If you’re welding a trailer or a building something on the side for someone then this kind of gas will be your best option.

The Pros of 75/25

- Better Aesthetics – When it comes down to it 75/25 just looks better. It looks flatter and not as rounded on top like Co2 would.

- Less Spatter – C25 also gives less spatter and clean up at the end. Of course this all depends on weld settings and a few other things but for the most part, you won’t have as much spatter.

- Works Good on Thinner Metals – With 75/25 it doesn’t get as hot like CO2 and will work better welding thinner gauge metals like sheet metal.

The Cons of 75/25

- Cost More – One

downside to mixed gases like this one is that they will cost more. At the end of this article, I’ll talk about where and how to buy gas for your MIG welder. - Narrow Penetration – Finally, with this type of gas you’ll get a more narrow penetration than compared to CO2. The top of the weld will be wider but it will narrow down to more of a cone shape the deeper the weld goes.

85/15 Gas Mixture

The next mixture gas is an 85/15 also known as a C15. Similar to 75/25 this gas has a mixture of 85% Argon and 15% CO2. These next few gases are ones that you’ll find more businesses using.

What is 85/15 used for? This type of gas is great for welding heavier metals like half-inch plate. It will give you a thick and wide weld that does great for filling in bevels.

I find this to work great for welding any heavy duty. For

Finally, 85/15 is also good gas to use for pulse spray for that heavy-duty weld.

The Pros of 85/15

- Good For Heavier Plate – When it comes down to it if you get something heavy to weld then this type of gas works for this situation.

- Does Good With Mill Scale – C15 also does

well with welding metals that have a mill scale on them. Mill scale is a carbon layer found on most mild steels that can chip offduring the welding process.

The Cons of 85/15

- Cost More – 85/15 is going to cost more. Argon is typically a more expensive gas but at the end of this article, I will share how you can cut cost on buying shielding gas.

- More Difficult to Weld – When you start to get into these higher-end mixed gases you’ll find that the weld puddle is more fluid and harder to control but with some practice, you’ll learn to control it better.

90/10 Gas Mixture

The last mixed gas I want to talk about is a 90/10 gas also known as C10 which has 90% Argon and 10% CO2 in it. This is the primary gas I use in my welding shop because of its penetration and aesthetic looks.

What is 90/10 used for? This type of gas makes a great fit for doing spray arc welding. I like to use this for welding heavier materials.

With C10 you’ll get a wide heavy and flat weld which looks great if you want a weld that is smooth and looks good for your customer.

The Pros of 90/10

- Spray Arc – If you like to run things like spray arc then this is the gas you’ll want. Spray arc is the process of turning down your wire speed and running a higher amperage.

- Little Spatter – this type of weld also gives very little spatter especially if you do spray arc.

- Looks Great – I mostly like this kind of welding because it looks great on the products I build for my customers.

The Cons of 90/10

Harder to control the puddle – The one big downside to this type of gas is that the puddle can be harder to control if you’ve not done it. A good example is doing a vertical down weld. However, it just takes time to learn how to read the puddle and how it will react.

Argon Gas

With Argon gas it is not a mixture but rather a specific type of gas use only certain types of welding. As you’re getting started you’ll want to know how each of these gas plays a role in getting the type of weld you’re looking for.

What is Argon gas used for? Argon is used for welding nonferrous metals like aluminum, titanium, or magnesium. You will need 100% Argon as it does not require any other gas mixture.

The Pros of Argon

It Welds Clean. Argon produces a very clean weld and bright weld. It also produces very little spatter. It may produce some silt which is a black looking dust. However, it can be wiped off fairly easy.

The Cons of Argon

Not a good choice for normal metals. If you’re planning to use straight Argon for your welding project just to save a few bucks from using a mixed gas then you may want to think again. You can weld regular mild steel with Argon but your penetration and welds won’t look the best.

You’ll need the right equipment. You’ll also need a welder that is meant for welding aluminum. You cannot use your typical Miller or Lincoln Electric welder for this.

I did this once to try it out and since the liner and rollers were the wrong setups I ended up snapping my wire off and causing more problems for myself. Instead, you’ll want a push-pull welder that is able to control the wire.

Argon is Costly. Finally, as I shared earlier, CO2 is a relatively cheaper gas and Argon is a bit more expensive. If you’re welding regular mild steal I recommend going with a C02 based gas before using Argon.

Stainless Tri-Mix

The final gas mixture I want to talk about is Stainless Tri-Mix. This is a tri mixture which means it is made up of 3 main gases. These gases would include 90% Helium, 7.5% Argon, and 2.5% Carbon Dioxide.

However, you can also use a mixture of 2% Carbon Dioxide and 98% Argon as an alternative option.

What is Stainless Tri-Mix used for? Stainless Tri-Mix gas is used for exactly what it says, welding stainless steel metal. However, not all stainless steel metal is meant for welding.

Typically a 304 or 304L grade stainless works the best for welding while other types of stainless are only good for bending and forming.

The Pros of Stainless Tri-Mix

Produces a Strong Weld. Using stainless tri-mix will give you the cleanest possible weld. This provided that you have your wire speed and voltage set correctly.

The Cons of Stainless Tri-Mix

Stainless Trimix is Expensive. I’ve used Stainless Trimix on several jobs over the years and Tri-Mix is not cheap.

Spatter is Hard to Clean Up. I’ve also found that stainless weld spatter is hard to clean up and remove with a typical chipping hammer and may require the use a hand grinder with a brush wheel.

Can Become Brittle. Stainless is naturally a harder metal and when you weld it can make it harder yet. However, if you weld it to hot and can make it brittle cause the welds to crack easier.

Can Warp Easily. The other problem with welding stainless is that it can warp if you get it too hot. Instead, make sure your gas setting are set correctly and try not to weld too much in one spot or for long periods of time.

Where to Get Shielding Gas

Finally, as I’m wrapping this helpful guide up you might be wondering where you can get these gases at for your welder?

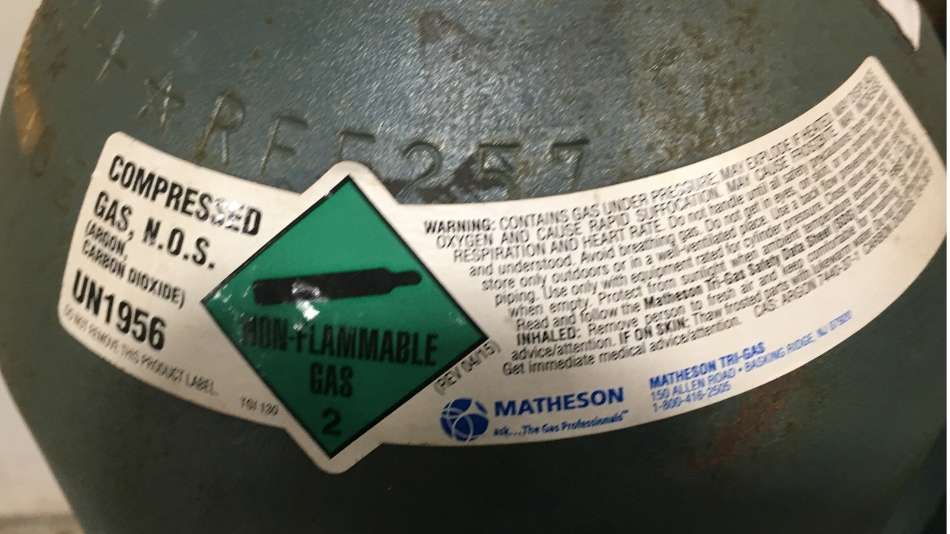

In most cases, you will be able to find them at a welding supply store such as Matheson Gas Supply. These types of stores will be able to trade in empty tanks for full ones.

I’ve actually been using this company for several years now and found them to be a great asset for my welding business.

Finally, take the time to shop around for the best prices and you should be able to find the welding gas you are looking for.

So what kind of welding gas do you use most? Share your answer down below.