Why is My Wire Feed Welder Not Working – 7 Ways to Fix It

If you’ve ever used a MIG welder you know that the wire feed can have issues from time to time. If you’re new to this then just know that these things happen and there are things you can do to fix it. So what can you do to fix a wire feed welder when it’s not working?

Check the power hookups to the head to see if they’re plugged in incorrectly. Then check the wire feed tensioner is not too loose or too tight. Make sure you’re using the right rollers, the liner or tip is not plugged, and if that doesn’t work check to make sure that you don’t have a bad welding gun trigger.

I know that’s the quick answer to what the problem could be, I’ll go into detail with 7 different reasons your wire feeder might not be working correctly and what you can do to fix this issue.

7 Reasons Your Wire Feed Welder is Not Working

Below are the seven main reasons the wire feed can stop working on your MIG welder. Try each of these to figure out which of them is the culprit.

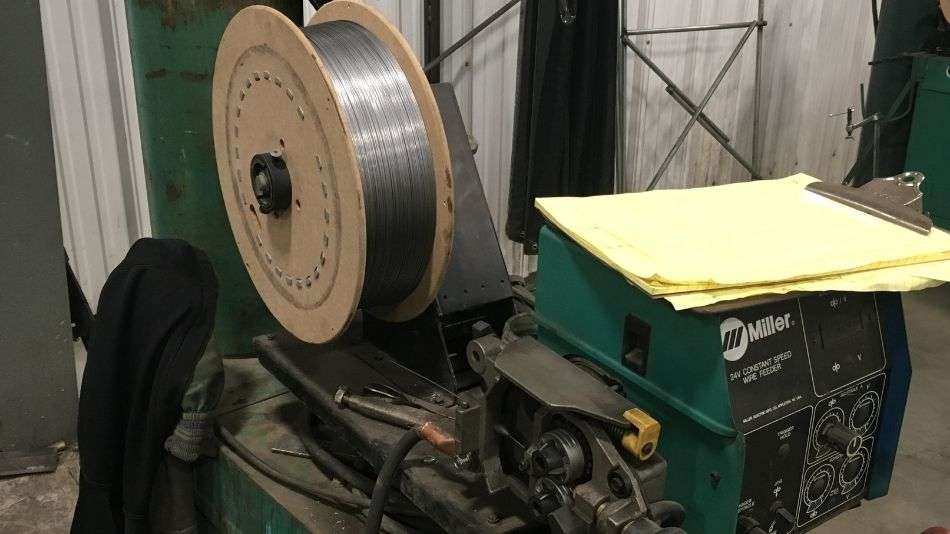

1. Power Hookup

The first thing to look into is the power hookup. The power hookup plugs into the head and gives it the power to pull the wire through the liner to the welding gun.

A lot of times these hook-up connections can become loose if not checked regularly. These hookups are typically twist and lock hookups and some are just a simple plug-in-go setup. Either way, check to make sure the hook-up is plugged in and tight.

Finally, check to make sure there is no spatter or dirt caught in between the plug-in and the hookup. Sometimes spatter from your weld can build up and cause the plug to short out or not push in all the way. Just make sure the plug is secured tightly.

2. Wire Feeder is Not Tight Enough

Next, you’ll want to check your wire feed tension so that is not too loose. If the tension on your welding wire isn’t tight enough then it won’t push the wire though.

Some welders will have handy instructions that will show you how tight your tensioner should be set. However, some welders don’t have this. The best way to fix this is to tighten the wire tension and keep checking it till the wire moves through the gun.

I’ve had this issue usually after I change a roll of wire and I start welding I find that I don’t have the tensioner set tight enough.

3. Wire Feeder is Too Tight

You can also go too far the other way as well. If you tighten the tensioner too much it can cause the wire to be harder to pass through the line.

Worse yet if you tighten it too much it can flatten the wire and not allow it to pass through the liner. I’ve had this happen to me and in this case, you’ll have to remove the flattened wire and loosen the tensioner.

Having the tensioner too tight can also cause the wire to break and cause a ball of wire to build up commonly referred to as a bird’s nest. To fix this loosen the tension on the wire and do some test welds.

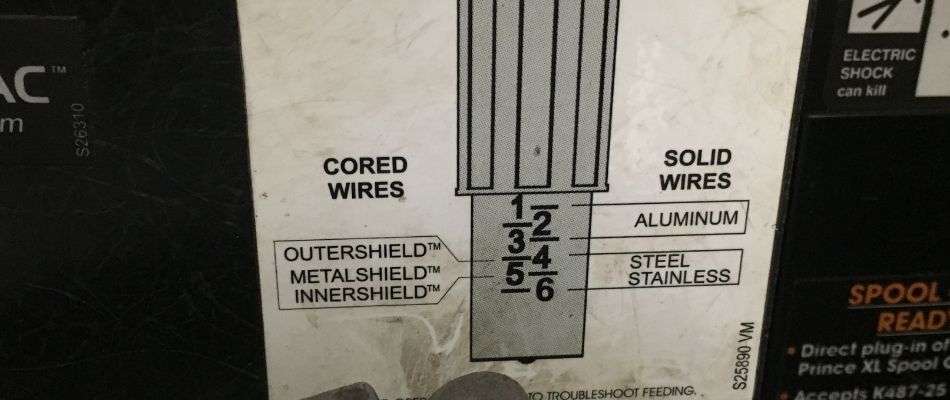

4. Using the Wrong Rollers

Next, you need to check if you have to wrong rollers set up in your welder. The rollers are what pull the wire through the welder. However, they need to be the right size for the wire they are pulling through the welder or they won’t work.

For example, if you’re using a .035 wire and you have a .045 roller it’s probably not going to work the best at pulling the wire through the welder.

To fix this you’ll have to check the rollers. They will have a number printed on the sides of them to indicate the wire size. So if you have a .035 wire and a .045 roller then check the roller because the roller may have the correct size on the opposite side.

5. Liner is Plugged Up

The liner could also be causing your problems as well. One big problem with welders is that they create a lot of dirt and dust that can land on the wire as if feeds through the machine.

Over time this dust and dirt can begin to fill up and plug the liner keeping the wire from passing through the welder.

There are a few things you can do to fix this. First, you can tie a clean rag to the wire before it feeds through the welder. This will wipe the wire clean and get a majority of the dust and dirt off of it. You can also put an old shirt or cloth over the top of the wire if it’s exposed to keep dirt and dust off of it.

You can also try blowing air through the liner with an air compressor. You will have to remove the wire from the machine to do this but it may be able to push some of the dirt out.

This works sometimes but if the liner is really plugged up you’ll have to get a new liner.

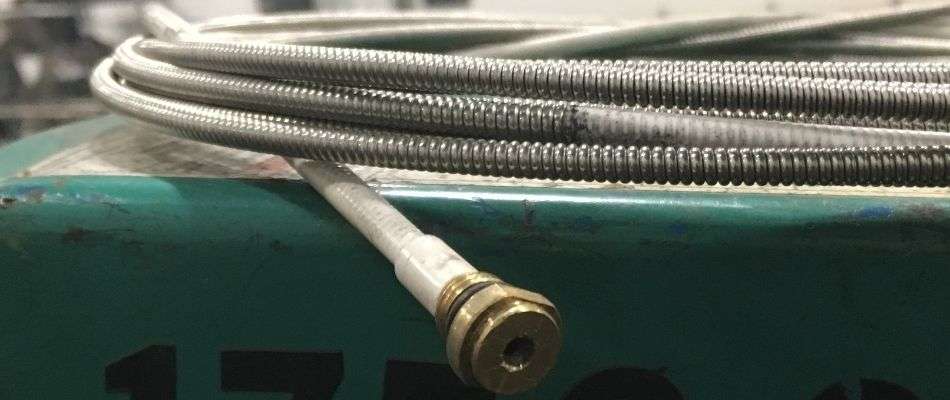

6. Tip is Plugged Up

Next, if the wire is not feeding through your MIG welder then you may want to check the tip. Just like the liner it can get plugged up over time as well.

On top of that, you’ll want to check the tip for the spatter. As you weld spatter can plug up your tip. If the tip is not cleaned up from time to time it will get plugged up.

Finally, if the welder is not set right it could it could cause burn back. This is where the heat from the welding causes the tip to melt at the tip and plug the hole.

To fix this issue start by taking the tip off. If it doesn’t come off the wire might have fused with the tip. In this case, you’ll have to twist the tip off and cut the welding wire to remove it.

If you can remove the tip check the bottom of it to see if there is any dirt building it. If there is remove it and you should be good to go.

If the tip is plugged up try using a tip cleaner to remove it. However, if nothing works you’ll have to get a new tip for your welding gun.

7. Bad Welding Gun Trigger

Finally, if your welding wire still won’t move through your welder then it could be the trigger on the welding gun. The trigger does go bad from time to time.

This can be due to excessive use, heat, weld spatter, and occasionally falling on the ground. Any of these things can damage the trigger on the gun.

If this is the case you may need to have a welding technician look at it to have it fixed.

Final Thoughts…

When it comes down to it any one of these problems could be the culprit. Over time as you weld more and more you’ll have a better understanding of how your machine works and what might be causing the problem.

So why is your MIG welder not feeding the wire through properly? Share your thoughts and comments below,