3 Best Welding Anti-Spatter Spray – 2024 Full Review

It’s no secret that welders deal with a continuous stream of spatter that can make for a messy clean-up.

Welding spatter not only affects clean-up but can also affect the job at hand. It’s fairly unpredictable, making treating and preparing for it even more complicated.

While there are things you, as a welder, can do to reduce spatter during your welding projects, there are also products to help you reduce spatter. Anti-spatter spray is a product that can help reduce spatter and simplify your processes significantly.

Whether you’re an experienced welder or a beginner, you know that minimizing your spatter makes a difference. Spatter is a known by-product of any welding job, but that doesn’t mean you must suffer from it while working.

In this guide, we will review the top 3 welding anti-spatter sprays. We will walk you through each one, tell you why we think they are the best, and share any cons you should know about.

Once we’ve reviewed the products, we will take you through a detailed buying guide to let you know everything you should know about working with welding anti-spatter spray.

The 3 Best Welding Anti-Spatter Spray Products Reviewed

We’ve narrowed your options down to our top 3 picks for anti-spatter spray options.

These anti-spatter sprays are what we determined to be the very best available online. We’ve sifted, sorted, and researched the options to bring you the top 3 anti-spatter sprays for welding.

#1 Cantesco AS16-A Red Heavy-Duty Solvent-Based Anti-Spatter, 16 oz. Box/Aerosol Cans

Cantesco AS16-A Red Heavy-Duty Solvent-Based Anti-Spatter

Our Take

The Cantessco Anti-Spatter Spray is a great solvent-based spray that does a great job at preventing weld spatter. Best of all, you can paint over it without any issues. On the downside, you can buy almost two cans of the Weld-Aid AntiSpatter and get 4oz more per can.

| Best For | Normal Welding |

| Price | High |

| Durability | Holds Up to Heavy Weld Spatter |

| Ease of Use | Easy to Use |

Not all welding anti-spatter sprays are created equally, and knowing you’re making a good choice can be challenging.

But we think this option from Cantesco is the best welding anti-spatter spray for the money.

No spatter spray, including this one, is perfect, but we still feel like this is one of the best options.

It works great more often than not and it’s suitable for various types of welding rather than designed to only work for MIG or some other welding form.

You get a 16 oz. can of red anti-spatter spray for one affordable price. There are cheaper options, but like we said, this one is the best for the money and is still not expensive. This spray is solvent-based and comes in an aerosol can.

Cantesco anti-spatter spray was designed to prevent spatter build-up through a non-flammable solution.

This anti-spatter spray is paintable and contains no fluorocarbons or silicone, making it safe and reliable. It dries quickly and is resistant to high heat as well.

Pros:

- Use this anti-spatter spray for your welding and then paint over it to keep your job looking nice.

- Heavy-duty spray that has a proven track record for reducing spatter build-up.

- The spray is non-flammable and free of silicone.

- Colorless spray that will not leave behind odd colors or residues.

- Only a small spritz is needed, so your can will last longer.

Cons:

- It is recommended to have proper ventilation to avoid fumes.

- It leaves a gel residue that you may need to wipe off.

Overall, we deem this one the best of the best. You probably won’t find a more reliable and affordable option wrapped up into a smooth bundle.

It’s so easy to use, and even though it’s a solvent-based aerosol, it doesn’t contain the silicone materials that put off hazardous fumes.

#2 Weld-Aid Weld-Kleen Heavy-Duty Anti-Spatter Liquid, 20 oz.

Weld-Aid Weld-Kleen Heavy-Duty Anti-Spatter

Our Take

The Weld-Aid Weld-Kleen Heavy Duty Anti-Spatter Liquid is one the best options, with its 20oz can giving you more than Forney and Contesco. Best of all, it works just as well as the other brands at about half the price of the Contesco brand.

| Best For | Normal Welding |

| Price | Low |

| Durability | Prevents Normal Weld Spatter |

| Ease of Use | Easy to Use |

This could be the one for you if you want the best quality welding anti-spatter spray.

This anti-spatter spray is a high-quality option. Weld-Aid is a known brand in the welding industry, and this highly-rated choice certainly has a lot to offer.

This particular option is 20 oz. aerosol can, but you can also purchase it in larger quantities, such as a quart or gallon option attached to a sprayer.

You can even purchase the larger ones with the spray nozzle and hose. This gives you a wide variety of options to work with.

This fast-drying anti-spatter spray was designed to protect your surfaces and help reduce the need for grinding and excessive clean-up maneuvers after you complete welding.

It’s perfect for high-amperage jobs and easily falls into our second-place pick. You will find that your tools, parts, fixtures, and surroundings are properly protected with this product.

Weld-Aid is a water-based solution that is bio-degradable and eco-friendly.

The solution is paintable and non-flammable, so you can always operate with ultimate safety. This is one of the more affordable anti-spatter sprays in a well-made spatter solution.

Pros:

- A water-based solution that does not contain any hazardous chemicals or materials.

- Protect your fixtures and tools from that annoying spatter with this simple spray.

- A 20 oz. Aerosol can mean you get more for your money.

- This solution is made to be non-flammable and contains zero fluorocarbons.

- You can purchase various size options from Weld-Aid, including a gallon bottle with a sprayer.

Cons:

- The nozzle tends to stop working before the bottle is empty.

- Best for random and small welding jobs rather than everyday welding use.

The best thing about this option is that it is fast-drying, which means you can get right to work when you use it. It’s a bit cheaper but still gets the job done and is highly cost-effective.

Clean-up will be quick and easy as you can wipe it away when welding, and your tools and accompanying assets will be protected from spattering.

#3 Forney 37030 Welders Anti-Spatter, 16-ounce

Forney 37030 Welders Anti-Spatter

Our Take

The Forney 37030 is also an excellent option for Welding Anti-Spatter Spray. It works just as well as all the other brands mentioned in this article but is priced a bit higher and the Weld-Aid brand gives you 4 more ounces at less money.

| Best For | Normal Welding |

| Price | Medium |

| Durablity | Prevents Normal Weld Spatter |

| Ease of Use | Easy to Use |

Forney provides us with a great option, one of the best welding anti-spatter sprays for MIG welding.

It doesn’t always hold up well on extra-hot welding surfaces but should do ok initially when spraying it. This is another more expensive option, but it’s reliable and well-made.

This anti-spatter spray is manufactured in China. It comes in a 16 oz. aerosol can and is simple to work with.

The mixture is silicone-free. It is designed to prevent welding spatter from messing with your MIG nozzles, contact tips, and more. You can protect your work surface and the surrounding welding area.

You don’t have to clean up this anti-spatter when you’re done, except maybe off your tools and accessories.

Your welding surface can be painted over; you don’t have to worry about clumps or discoloration. Any residual needing to be cleaned up can be wiped away easily.

This is a lesser-known anti-spatter spray, but it earned its spot in our 3rd-place ranking. It’s easy to use, non-toxic, and effective for a decent price tag.

There’s not much information about this product, but it’s not a new brand, and Forney also produces several other welding products.

Pros:

- Simple to use anti-spatter spray

- This anti-spatter spray is silicon-free.

- Clean-up is very easy; wipe it off or paint over it.

- Designed specifically to work with MIG welding needs but can be functional for other types of welding as well.

- This welding anti-spatter spray is highly effective and pleasantly surprising.

Cons:

- It must be sprayed while your metal is cold before welding or heating your surface area for the best results.

A Complete Buying Guide for Welding Anti-Spatter Spray

We can share welding anti-spatter sprays with you all day, but in the end, you may not know which option you should go with. There are so many options on the market.

While we researched and reviewed to bring you our top 3 picks, there is still a lot of information to familiarize yourself with before you make a decision.

That’s why we’ve compiled a simple buyer’s guide to give you all the most important information and help you decide.

Anti-Spatter Spray Explained

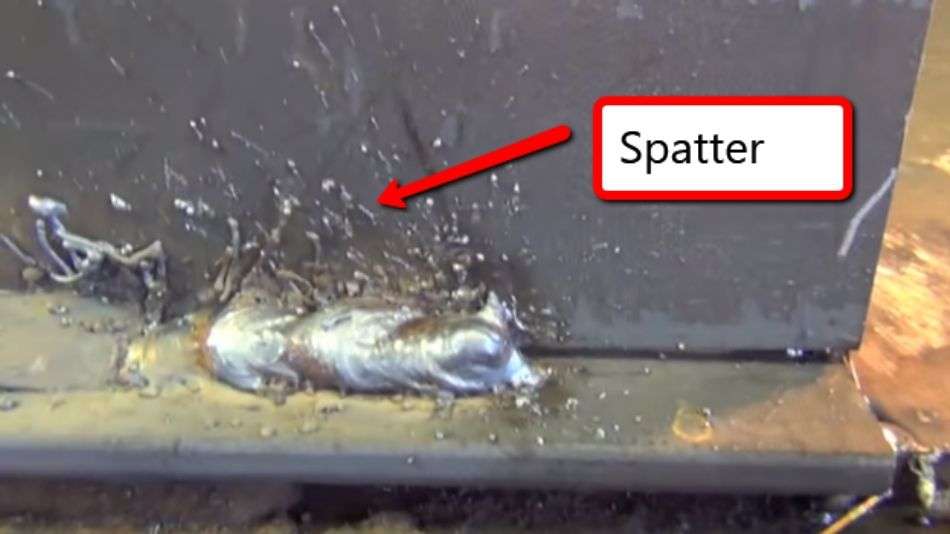

When you’re welding away, sparks and arcs of light can leave behind a mess when you’re done.

You can take steps as a welder to reduce spatter, but an anti-spatter spray is one of the most effective protection means for spatter.

You coat your surface and even surrounding surfaces and tools with the anti-spatter spray, and they are protected from those sparks and arcs.

Most of these sprays are a silicone-based substance (although they may not contain silicone) that causes the spatter to roll off the surface.

Anti-spatter spray can be water-based or petroleum-based, and the ultimate goal is to prevent the spatter from sticking to a surface area.

Then when you are done with your welding job, you can wipe up the spray and the spatter (notably didn’t stick) and move on with what needs to be done.

There is no grinding or extensive cleaning and no low-quality seams thanks to the spatter. Instead, you get a clear, clean surface that looks smooth and polished, thanks to the lack of spatter.

Spatter is Bad

You may be rolling your eyes, thinking spatter isn’t a big deal. Or maybe you find yourself such a talented welder that your spatter is incredibly limited.

Spatter is not just about the sticky mess it makes but also about the overall look and skill of your jobs.

If you let your worksite become a spattered mess, you will spend a lot of extra time chiseling, brushing, and grinding various spatter messes. Think about how you can use that time to work on another job!

Forget all the awful clean-up and rely on an anti-spatter spray to make it a bit easier for you from start to finish.

Here are some things that are not appreciated about spatter and should push you towards admitting that anti-spatter spray can be quite helpful.

- Spatter can stick to the workspace and surrounding areas, leaving a mess.

- Spatter means wasted materials left in a mess rather than used for welding.

- Spatter can be damaging to your clothing and your workspace.

- Spatter leaves seem bulky and low-quality.

- You have to spend time cleaning when you could be working.

- Spatter can build up on your tools and materials, making them ineffective or requiring your cleaning time to get them back to how they should be.

Stop the spatter and improve your welding experience clean-up. Anti-spatter spray is not expensive. It’s a simple, affordable tool that should always be a part of your welding toolkit.

What to Look for in Anti-Spatter Spray

Most anti-spatter sprays are made quite similarly. There are just a few variables you should be familiar with and know to look for. Here, we will break them down for you further.

Ingredients

While you won’t find an ingredient label, you can be sure that your anti-spatter spray is not full of toxic chemicals you will need to worry about.

Please pay attention to whether the spray is non-flammable, and check the labeling for things like fluorocarbons, as this is a material we recommend you stay away from.

Type of Finish

Think about how you plan to finish your job when you are done. The anti-spatter sprays that we shared here are all paintable. This is the most common type of spray.

It’s typically made to be water-based and silicone-free, and you can paint over the surface when you are done welding.

Some sprays are made for grinding finishes; sprays are recommended when your surface has no finishing plans.

If you know you will grind the surface or are unsure how it will be finished, you may want to use an oil-based spray to prevent surface oxidation.

Of course, if you are grinding, you could skip the spray if you want, but the spray can help your surrounding areas even if you intend to grind the work surface.

Reducing Spatter Through Welding

You can also do a few things while welding to help reduce spatter. One of the best things you can do is practice and hone your skills to avoid causing as much spatter.

Here are a few simple things you can put into practice that might help reduce spatter in your work area.

- Understand your settings. You will have excessive spatter if your amperage or voltage is too high. Be sure your settings fit the job you’re doing.

- Use the right wire feed speed.

- Perfect your welding arc length (too short or too long can cause extra spatter).

- Thoroughly clean all work surfaces to reduce spatter.

- Use a high-quality welding machine.

- Use high-quality tools and accessories, particularly rods and wire.

- Replace CO2 with argon.

- Learn how your angles can affect your spatter.

- Avoid using globular transfer modes as they cause excessive spatter.

- Be familiar with your surroundings, excessive moisture or humidity in the air might cause excessive spatter when welding.

Anti-Spatter Spray Alternatives

If you purchase an item to help reduce your spatter, you might as well go with the real deal.

We recommend that you add spatter spray to your arsenal. However, if you find yourself in a bind and you run out unexpectedly or misplace your spray can, there are some things you can try.

Spatter spray is an anti-sticking oily residue that keeps the spatter from sticking to the surface. If you need a quick-fix solution, try using cooking spray.

It’s not quite as effective as the spray designed for spatter protection, but it could help you in a bind.

Another common recommendation is WD-40, but be careful as it’s not a safe option.

You can use it to protect your surrounding areas, but we wouldn’t recommend using it directly in your welding area.

Our Top Pick

Overall, we found the Cantesco AS-16 to be the best option for the price.

This anti-spatter spray dries quickly and produces the best results overall. Clean-up is simple, and the spray is highly effective.

You can’t go wrong with this option for any welding job or project.

Conclusion

When it comes down to choosing the best welding anti-spatter spray, you need to determine which you think will work best for your needs.

We’ve shared our top pick with you, but each of the three products we shared is noteworthy, and they rightfully earned their place in our ranks.

Consider your budget for an anti-spatter spray, and remember to choose based on your preferences. We think you will find yourself satisfied with any of these products.

We hope that you have found this buyer’s guide to being a helpful resource in finding the best spray options and providing you with reliable information for your selection process.